NORMA Group at a glance

10,000 customers in 100 countries

more than 40,000 product solutions

EUR 1,15 billion sales in 2024

8.0% EBIT margin in 2024

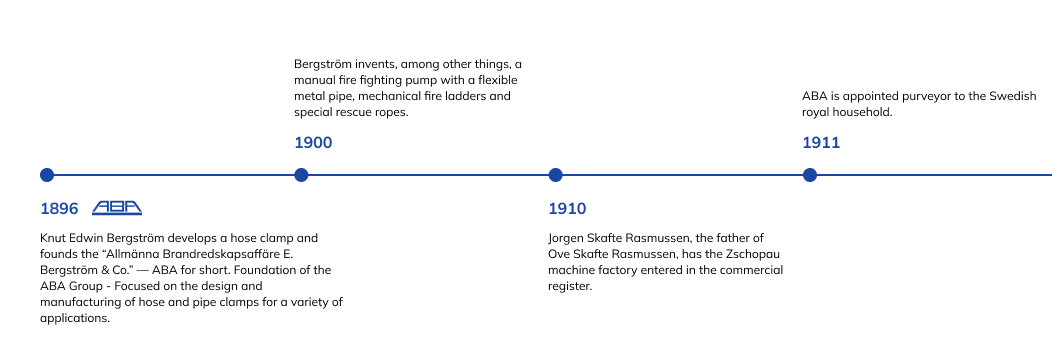

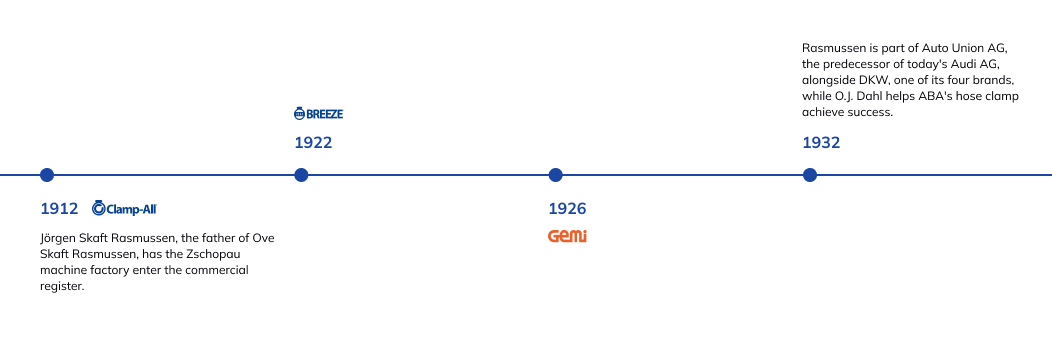

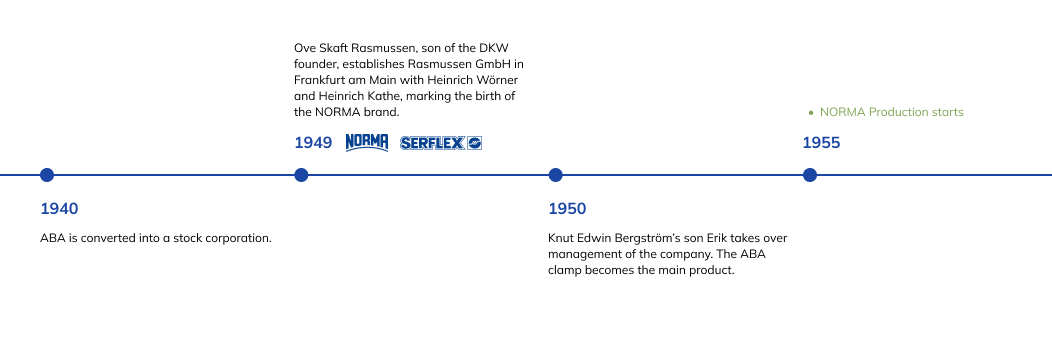

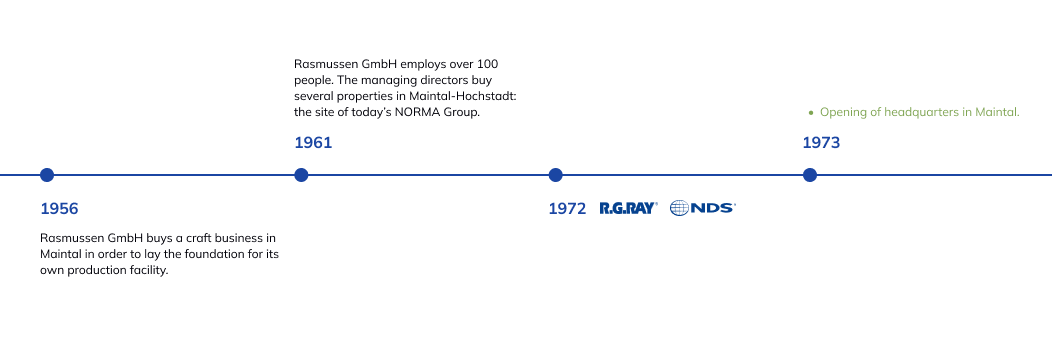

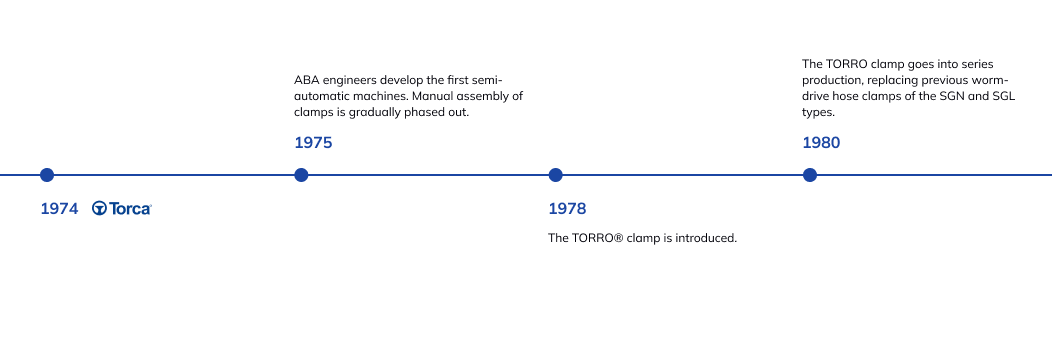

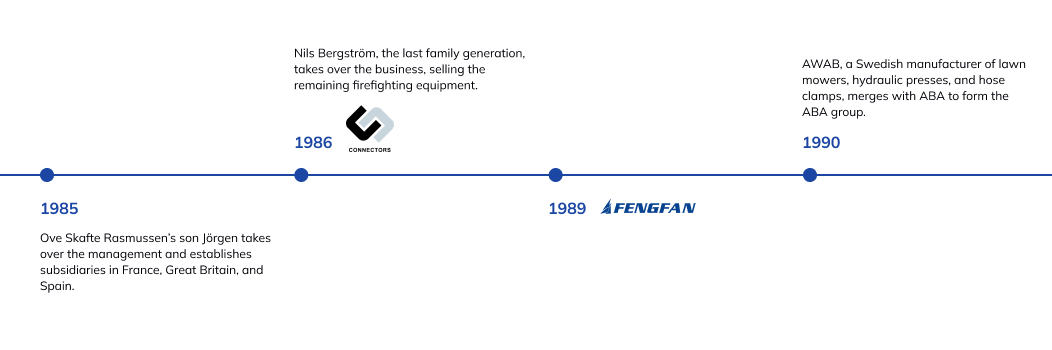

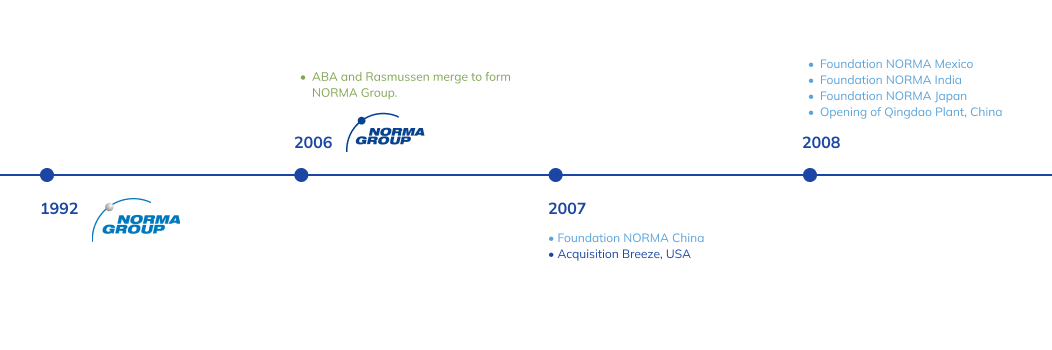

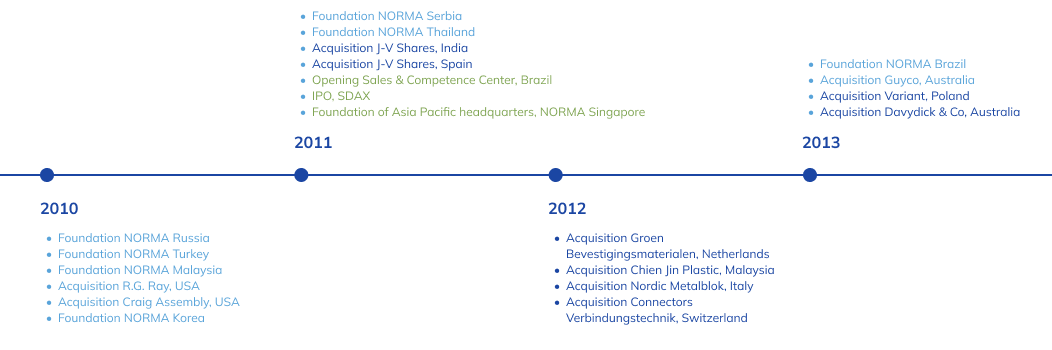

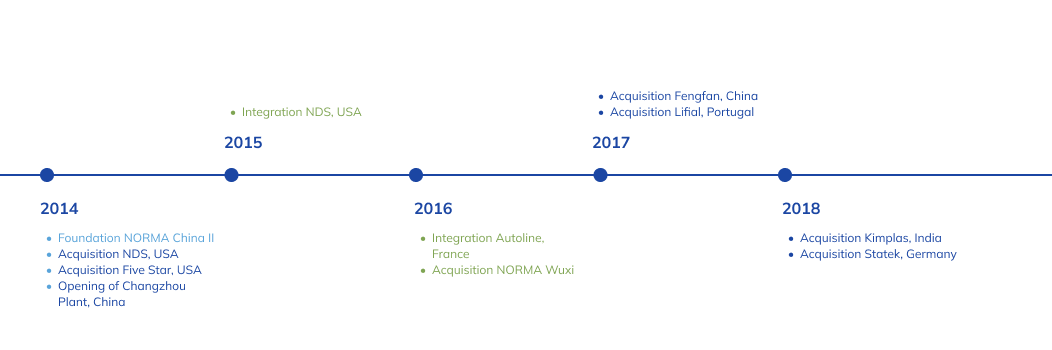

125 years of history

25 production

sites

~7,800

employees

Mark Wilhelms CEO since 2025

Investors

Since 2011, we have been listed on the Frankfurt Stock Exchange and included in the SDAX index. Through a diversified product offering and strategic investments in growth markets, NORMA Group aims to create long-term value, while building credibility through transparent and continuous communication with our shareholders. Click below for the latest information, reports and contact details from our Investor Relations team.

Brands and products

Each of our brands is a leader in the field, with best-in-class experience and expertise to deliver superior, on-target solutions. As technology races ahead and shapes tomorrow’s demands, our brands evolve to incorporate cutting-edge developments into their products and solutions.

Our brands have acquired a solid reputation for performance and cost efficiency, and our products are synonymous with quality and safety. The sum total of all our brands and their products is a range that is as extensive as our customers’ needs. In short, there is a solution from NORMA Group for every connection need, context and industry challenge.

Quality

Our quality standards have been carefully developed over the years through working closely with our customers in the most challenging and diverse situations. NORMA Group works to an absolute standard of quality that we first and foremost set for ourselves. Here, safety and environmental performance are the drivers. We proudly bear all relevant international certificates and ISO standards.

Engineering

Staying ahead in business today calls for fresh insights and breakthrough engineering ideas. NORMA Group rises proudly to the demands of the times, making sure we always have the future at our fingertips. We actively identify technological trends early, using Innovation Scouts to create roadmaps that guide us into new areas of advancement. As a result, our innovation methods and management processes are industry benchmarks, with 300 expert engineers focused on developing innovative solutions.

- slide1

- slide2

- slide3

- slide4

- slide5

- slide6

- slide7

- slide8

- slide9

- slide10

- slide1

- slide2

- slide3

- slide4

- slide5

- slide6

- slide7

- slide8

- slide9

- slide10

- slide11

- slide12

- slide13

- slide14

- slide15

- slide16

- slide17

- slide18

- slide19

- slide20